Your home may have been built with a crawl space under the basement floor. The floor system is one of two types structurally engineered I’m aware of. One is a wood framed floor joist system just like any framed house but with a crawl space. The other if a reinforced cement floor engineered with steel also above a crawl space. There should be one crawl space access and in this, you should find a Humidistat device that is controlling a fan/blower in a typical 8″ round vent pulling he outside air (which can be below freezing) from one or more round ducts in opposite corners of your basement. Yes, this was a minimum code requirement but it does not mean it was the right way to take care of possible growing mold under your home.

Mechanical Floor Vents Instead Of Outside Air

The outside air vent that allows the air flow into the crawl space remains attached to the house and the humidistat still controls the fan turning on and off. The 6-8 inch duct running down the wall into the crawl space below would be removed and the vent gets plugged with insulation. You could have the vent removed and then patch your exterior wall but there’s no need for this. The hole in the floor gets patched in as this outside air is what you want to stop letting into the crawl space during the winter. When outdoor air temperatures below 30F air reaches the warmer crawl space air, you make more moisture called condensation and this will only help mold to grow better. The mechanical floor vents are a duct device with a damper that closes by a weight inside when the fan is off and open upon air current allowing air flow from the lowest point of your interior space only. The following image is and example of a 4″ x 10″ none closing floor grille;

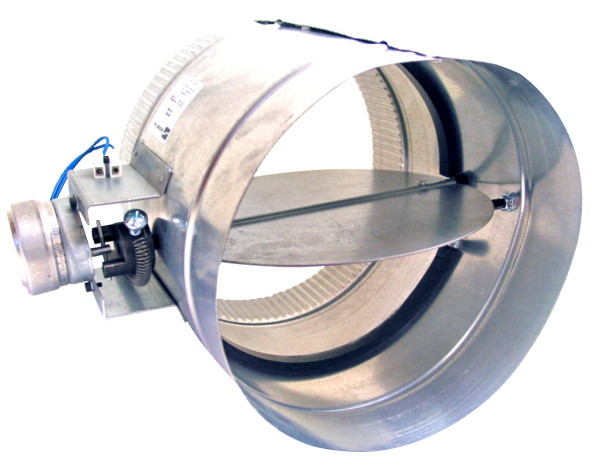

The coldest air is at the floor and this interior air is not condensed air and will not allow mold to grow easily and since it’s not pulling in subzero temperatures, your heating bill will go down too. Send me the savings, ok? Two of these are on the plan typically and will appear as a normal looking heat register does but the HVAC guy will mount a transition duct for the floor registers to 6” round and the following images are an electric type damper as an example;

An electric type damper can be controlled by the humidistat but I’m old fashioned and know that the fan air can open it on its own and this is what those types look like;

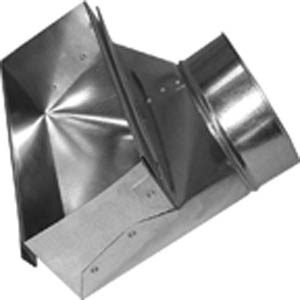

The following image is an example of the duct transition for the 4″ x 10″ to 6″ round; this is mounted in the floor opposite end of crawl space from exhaust fan;

Since code requires combustion air from outside to the furnace and hot water tank, you’ll still achieve fresh air inlet even if venting for radon mitigation as well although this would depend on the levels of radon tested. In some cases in basements with engineered floors and a crawl space, additional radon mitigation with separate controls is required. Keep in mind that with combustion air coming in, you’ll still be venting the crawl space and exhausting bad air and radon gas yet keeping it dryer.

As for this crawl space venting, if you don’t hear the fan running, that should be a concern and have it tested. Either someone got tired of it running all winter and turned down or off that humidistat or the fan burned out. Trust me, I know enough about this and learned it from Oakwood homes years ago as they stopped us on a basement project to rip up the floors, fixed the mold issues with bags of lime, new plastic and reinstalled the floor but with this method I’m suggesting. The supervisor told me out of the corner of his mouth that Oakwood was doing this to all their current homes to prevent law suits. Well people were getting sick from the mold growth. It works well and is above minimum code requirements which are always a far better thing.

You can leave your current system and ignore this suggestion if you wish but logically speaking; all homes built with just a crawl space foundation and no basement had manual vents that you had to close from the outside in the fall and open again in the spring time. With expansive soils in Colorado, these engineered wood or structural concrete floors came about many years ago because normal concrete floors would heave and cause huge damage to the home above. One reason many basements there have floating walls framed on concrete. So in short, code requires that space under your floor called a crawl space to be vented the same. But knowing a fan had to be the way to pull air through, it became part of the minimum code but they didn’t want the fan running all the time so to just control moisture, the humidistat was added into this code. What they missed was a temperature controller but regardless, there’s no need to pull in such cold air all winter long nor do you need extremly hot air in the summer under your floor rising up. Then you have to run more cooling. slash AC. You have enough of this coming in the combustion air ducts at the furnace area that waste energy. And remember my caution if using this system to also satisfy radon mitigation, it may not be enough and testing should be done to see how high the levels of radon gas are. It really should be a separate system.

Don’t miss reading my current blog; Basement Finishing 102

Don’t miss reading my blog Basement Finishing 101 if you still don’t have a design and look for Basement Finishing 103 regarding building your basement and another similar topic How To Finish A basement Yourself. Thank you and please Contact Me no matter what your question might be.