One more option for you on the plan is using XPS foam insulation panels or and foam panel with insulation properties that is, provided you have bare concrete walls or wish to remove all the cheap blanket wrap insulation the builder stuck to the walls just to meet minimum code. If you see this light blue color around your perimeter walls on my plans that are only on the exterior, not garage walls as you may read up on this option; it’s to show a method to build and meet code. Visit, https://www.buildingscience.com/documents/bareports/ba-0309-renovating-your-basment/view and another good article at this link; https://www.homeconstructionimprovement.com/how-to-insulate-basement-walls/ if your plan shows an orange/yellowish color around the perimeter walls, this is the existing blanket wrap insulation at a 3” gap/space. You are allowed to remove it and replace with a foam panel process or remove it and space your wall framing just an inch away for more floor space and insulate the framing stud cavity with R15 batt insulation. Just ask me to adjust for whichever you desire to do.

This is one maker of the good 2” XPS foam panels; Johns Manville R-13 (Common: 2-in x 4-ft x 8-ft; Actual: 2-in x 4-ft x 8-ft) AP Foil 1 Faced Polyisocyanurate Foam Board Insulation https://www.lowes.com/pd/Johns-Manville-Common-2-in-x-4-ft-x-8-ft-Actual-2-in-x-4-ft-x-8-ft-AP-Foil-1-R-13-Faced-Polyisocyanurate-Foam-Board-Insulation/3851107 Google best way to install foam, this is one guys method I think works ok!

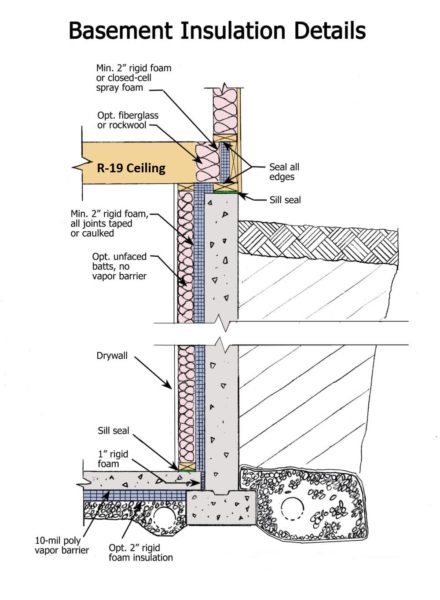

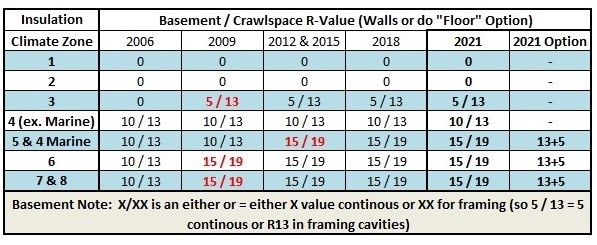

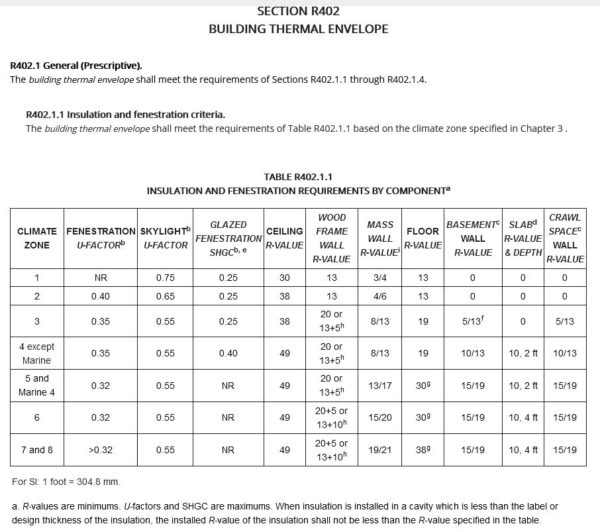

Basement “Blanket wrap insulation” left on basement foundation walls satisfies the continuous vapor envelope yet this method might not be enough R value, so do the math. Foam should satisfy the vapor barrier required and a thinner foam R value must be added to whatever you install in the stud cavity combined. Another way to frame to meet code R19 is just to gap the 2X4 framing 2″ from the concrete and install R19 bat insulation in the stud cavity. Check to see if you have foam on the exterior first then calculate what’s needed using per zone the Insulation Requirements & 2021 IECC First Look And current 2021 IRC Codes require the following;

N1102.2.8.1 (R402.2.8.1) Basement wall insulation installation

1-inch or thicker rigid foam panels (specifically EPS or XPS) often function as a vapor barrier in basements when properly installed. They prevent moisture from entering from the concrete, provided the joints are sealed with tape and gaps filled with foam sealant. While 1 inch is often sufficient, 2 inches is recommended for maximum protection.

Key Considerations

- Vapor Barrier Function: Rigid foam boards act as a vapor barrier and insulation, preventing mold growth.

- Installation: Panels should be installed tightly against the masonry wall, with joints taped (foil tape) and edges sealed with foam.

- Thickness: While 1-inch thick rigid foam acts as a vapor barrier, 2 inches is recommended for better thermal, moisture, and vapor protection.

- Alternatives: Closed-cell foam is highly effective as a vapor barrier, but open-cell foam should not be used as a primary moisture barrier.

- Code Requirements: Rigid foam boards at some point must typically be covered with drywall for fire safety.

If you are using 1-inch foam, ensure it is properly sealed at all seams to maximize its effectiveness.

Basement & Crawl Space Walls:

There have been no increase to this one either since 2012 but, they did add in an Option for those with basements only in CZ 5 – 8 (okay & Marine 4). Now you can have R13 inside as long as you have R5 outside instead of having to do R15 exterior only or R 19 batts. Basically, this allows for 2×4 framing to be used for exterior basement walls instead of 2×6’s. With concrete walls not wood framed exterior ones and since you’re framing the inside perimeter, if spaced with the 1” gap, use R15 batt insulation in the cavity at the least. Polyurethane sheeting is a typical vapor barrier that contractors use to prevent moisture from penetrating the walls of a basement. The material is stapled to the frame of a basement wall before it is finished with plaster or drywall. A vapor barrier is also helpful to keeping a basement insulated and warm. Follow code but I don’t believe in the vapor barrier in basements and you can read another man opinion of why he also feels this way; https://buildingadvisor.com/basement-vapor-barriers/

I note all my plans with this as a reminder;

“ALL PERIMETER WALLS FRAMED 2X4 16″-24″@ CENTER GAPPED 1-2″+ FROM ANY CONCRETE FOR VENTING TO PREVENT MOLD BUILDUP ALSO USING VAPOR BARRIER ON WARM SIDE OF WALL; ANY RATED FOAM MEETING CODE OR OPTION FOR XPS FOAM GLUED & TAPED AS PER PLAN; R15 OR HIGHER CONTINUOUS INSULATION, R19 CAVITY INSULATION IN FRAMED WALLS GAPPED 2″ OR COMBINATION OF BOTH WITH 1-2″ FOAM PER IRC CODE. R-VALUE TO BE DETERMINE BY THE IECC CLIMATE ZONE MAP, REFER TO TABLE R402.1.1 INSULATION AND FENESTRATION REQUIREMENTS BY COMPONENT”

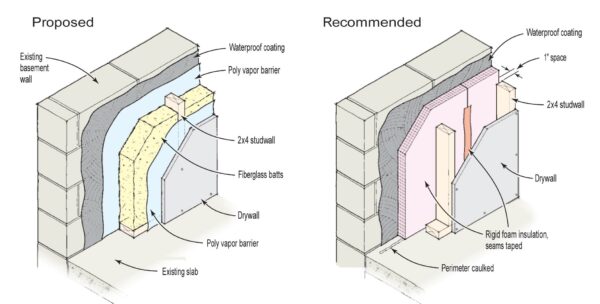

If you’re visual like me, the following image tells all;

In the image above, the “Proposed” method works because the vapor barrier by industry standards and building codes typically require a minimum of 6 mil polyethylene sheeting for effective moisture control, with 10-20 mil preferred for durability. This adds extra labor and cost anyway so why not just install the foam panels first? The “Recommended image is now missing the R15 bat insulation if a 1” foam. Proposed (often polyethylene sheet) and recommended (typically breathable/smart retarders) vapor barriers in basements differ mainly in moisture management. While traditional poly creates a strict barrier, modern recommendations favor breathable options to prevent trapping moisture against concrete, which can cause mold, mildew, and rot.

Click here for other basement topics; https://basementdesigner.com/category/basement-topics/

If your finding this from a web search and interested in a free quote for a basement design, just click here; http://basementdesigner.com/contact/